robotic filament winding

PRECISION, AUTOMATIZATION & STRONGER

MANUFACTURING

What is filament winding?

What do we do?

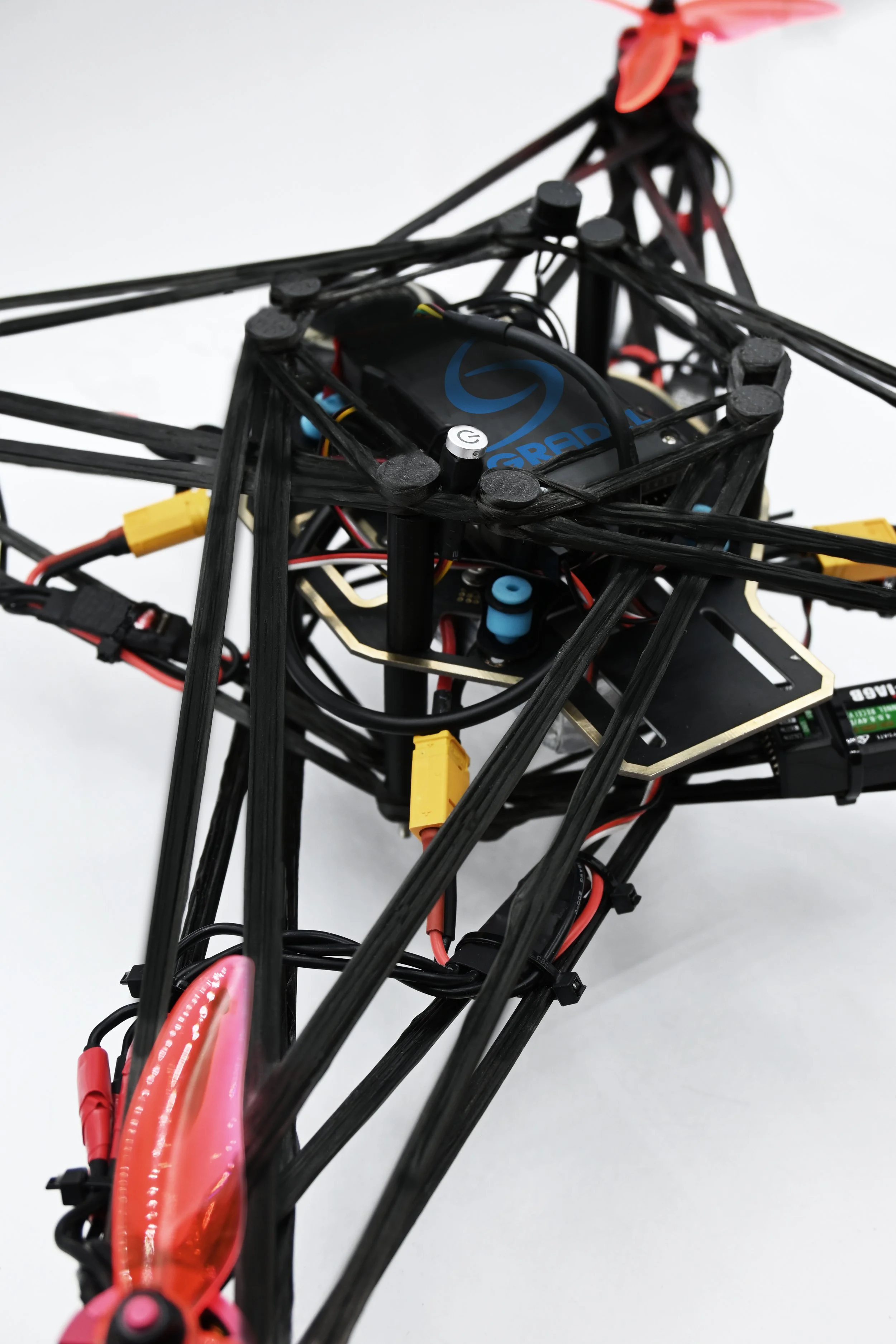

Filament winding is the process of wrapping a thread of fibres mix with resin around key points to create a structure, often called a composite because of this mix of materials.

This structure has the characteristic of being more than 60% lighter but equally strong and resistant to other materials such as metals.

We added versatility, precision and our experience making custom machines and called it:

(GRADEL Robotic Additive Manufacturing)

Our Services

-

GRAM Products

Explore infinite fiber & resin combinations for multiple market applications.

Available for Research Centres and Universities.

-

Aerospace Projects

High Complexity parts developed under the most extreme conditions to perform in space environments in collaboration with European Space Companies.

-

Cases & Applications

We have with Start Ups and Large Automotive Makers explore how we can help them reduce their carbon footprint redesigning key components into lighter stronger composites.

-

Research Projects

We are deeply integrated into the Research Environment in Europe, collaborating in many R&D EU projects. We are validated by ESA, LSA among many others.